CIRQLR's Dynamic Journey

Where we have come from, where we are going

CIRQLR is on a journey of dynamic growth

For the past two years we have brought into our Company like-minded regional leaders all united in a vision to give waste a second life. We help customers and the UK economy retain more of our valuable resources, improve materials security, reduce waste to landfill while increasing recycling rates, all to drive the nation towards greater circularity and growth.

Today as a nation we consume raw materials at the pace as if we had three planets to extract from. By recovering more secondary raw materials and giving them a second life, we will enable the Government’s industrial growth plans while at the same time reduce the burden on virgin raw materials and the emissions which stem from their extraction.

Together CIRQLR across its regional network of operating subsidiaries cares for:

• 19 waste & recycling facilities

• 8 MRFs – Materials Recycling Facilities

• 10 TS – Transfer Stations

• 600 staff

• Over 300 vehicles

• £150m of annualised turnover

We reinvest all this for further growth

Find out more about our operations at Castle Environmental, Chambers Waste Management, Cox Group, Eco Waste and Recycling, Ellgia, KP Waste, Select Environmental, Wilrose.

Industrial Strategy, Recycling Infrastructure

CIRQLR has through its operating subsidiaries made significant investments into recycling and materials recovery infrastructure. We are primed to invest at least £100m more into new modern recycling infrastructure over the next five years, all to help business and the public sector realise the Government ambition to create a more circular economy.

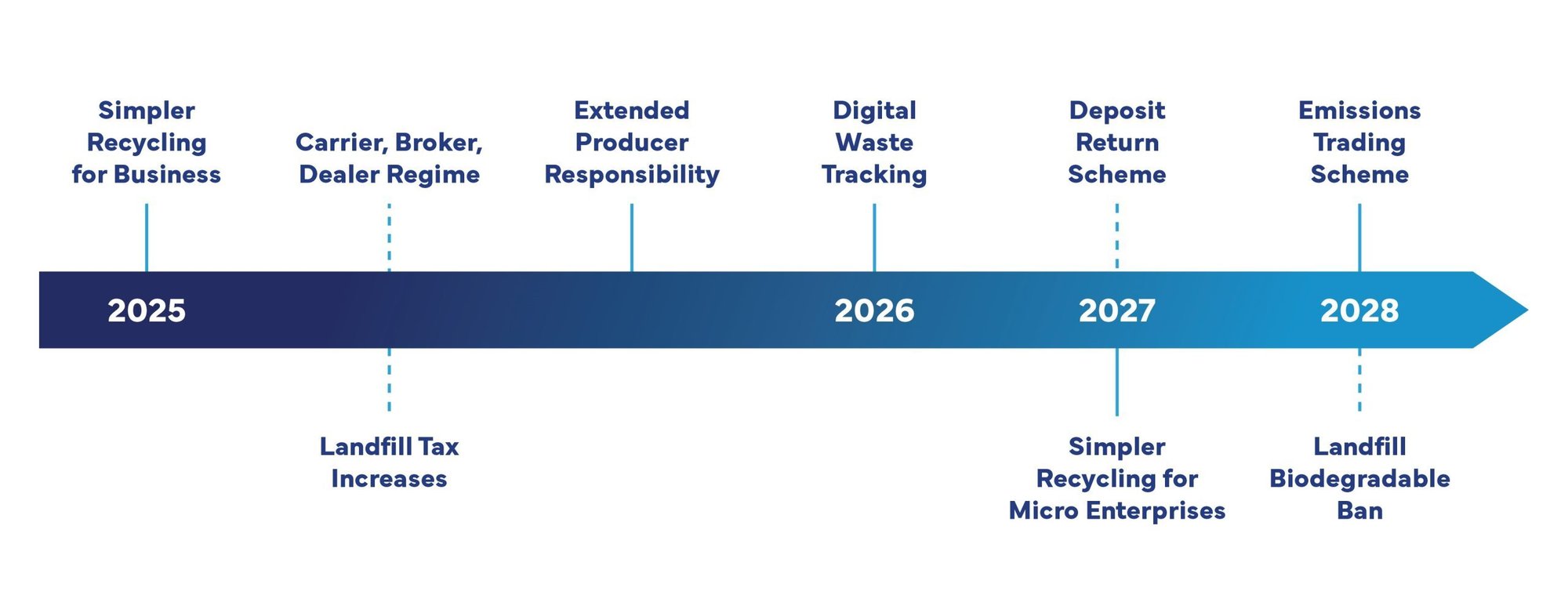

This new recycling infrastructure will be fit to adapt to the raft of changes underway over the next years to support business and Government’s twin-desire to transition to circular economy and underpin a policy and shared vision of economic growth.

CIRQLR has been growing its network of operations and adapting its offerings to be best placed to help with these reforms – Simpler Recycling, Extended Producer Responsibility for packaging and a nationwide Deposit Returns Scheme for drinks containers.

At CIRQLR we have the investment necessary to equip your business to meet its circular ambitions.

Green Jobs

New jobs will be created and CIRQLR expects to double its workforce to over 1000 over the next five years as it expands its footprint across the North, Midlands and South-East of England and develops its infrastructure and services offerings.

Minimising waste and increasing volumes and rates of recycling means fewer emissions from residual waste disposal and more resources circulating in our economy through the extraction of secondary raw materials.

Ours is a CIRQLR vision which looks to capture more materials so they can stay longer in circulation. The prevention of materials loss into the waste stream reduces the impact on the earth’s finite natural resources.

The time for the creation of greater local circularity and capture of secondary raw materials has never been more pertinent.Strengthening our local manufacturing base through the application of an industrial strategy becomes even more urgent in times of heightened global trade restrictions.

By giving waste a second life, we can reduce the economy’s over-reliance on imports, stabilise material supply, and create the green jobs that we all need.

The £10bn infrastructure unlock

New recycling legislation will drive growth in recyclables

Find Out More →

Find Out More-

- The move to a fully circular economy is at a tipping point. The sector twenty years ago was waste-focused, almost entirely dependent on landfill treatment, and is now focused on capturing materials and value. The recycling journey is only half complete, with over half of materials used still not recycled. – CIRQLR’s Views

10 10 10

- Over the next 10 years up to 10 million tonnes of “second life” materials will be recoverable for reprocessing back into the metals, glass, plastics, paper and card used in packaging. £10 billion worth of business investment is needed to build all the domestic recovery and recycling infrastructure needed to capitalise on that opportunity. CIRQLR is at the forefront of the private sector readiness to invest and help Britian build back better. Today the UK exports for waste or recycling:

- 600,000 tonnes of plastic, 1.6 million tonnes of RDF (energy), 8.2 million tonnes of metal, 37,0000 tons WEEE (electronic).

Tomorrow’s opportunity is that, once Simpler Recycling and EPR for Packaging (pEPR) regulations bite, official forecasts are that the markets for the packaging materials available for reprocessing will grow from 2020 levels as follows by 2035:

- Glass – Up 22%, to 2 million tonnes.

- Capacity investment opportunity – 72,000 tonnes per year

- Metals – Aluminium and steel UP 24%, to 550,000 tonnes per year.

- Capacity investment opportunity – 203,000 tonnes per year

- Paper/board – Packaging UP 39% to 5.3 million tonnes per year.

- Capacity investment opportunity 1.7 million tonnes per year

- Plastic – Packaging UP 52% to 1.6 million tonnes per year.

- Capacity investment opportunity of 324,000 tonnes per year

- The plastics capacity opportunity for UK investment could be greater depending on the outcome of consultation on a government proposal to ban the export of plastic wastes to non-EU countries and non-OECD members ( Organisation for the Economic Cooperation and Development).

- Separately collected Food Waste UP 100% to 4.8 million tonnes per year.

- Potential forecast investment opportunity for Anaerobic Digestor facilities of 1.375 million tonnes per year. This will depend on whether closed composting facilities cannot provide an extra capacity outlet for separate food waste eg via mixing at the front gate.